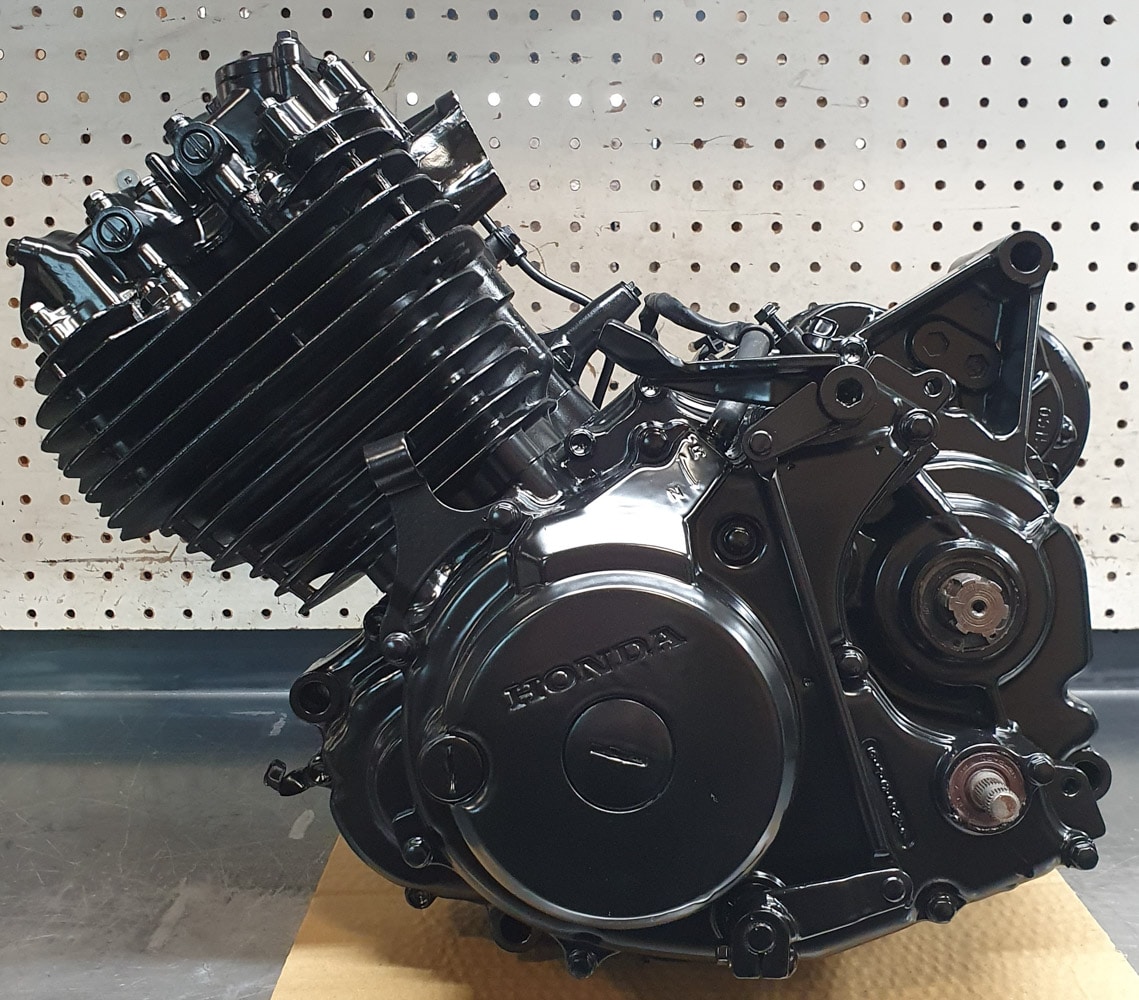

Thanks to the sponsorship between Raven Media and CVTech AAB, a 1987 Honda 250 ATV engine has been brought back to life.

This engine is now in new condition (out of the factory).

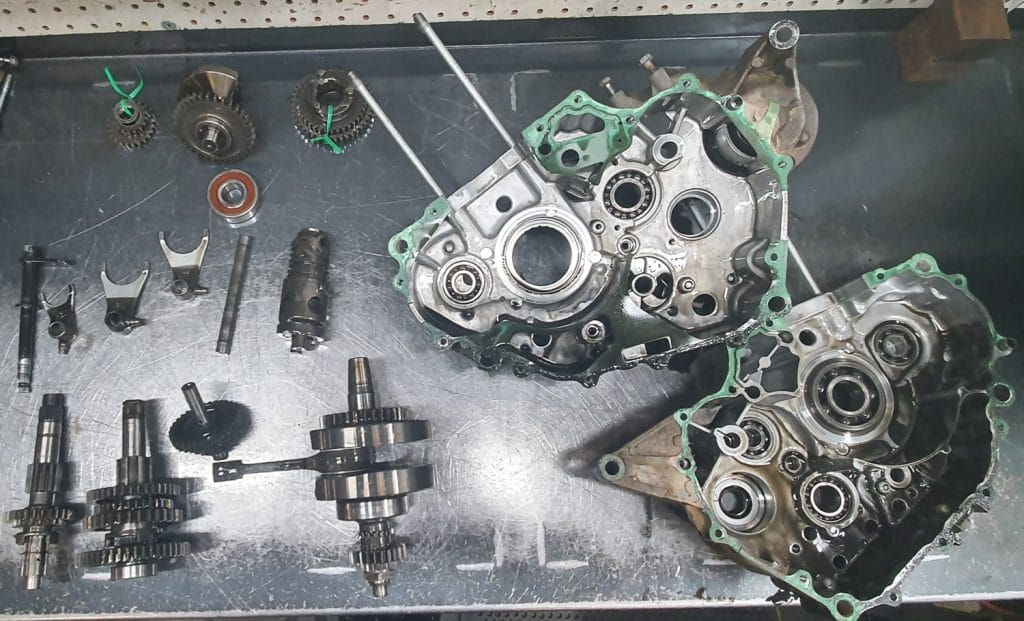

CVTech AAB performs a complete analysis of the engine’s condition by disassembling it to determine which parts are damaged and which are not.

Based on the analysis, an estimate is made of the total cost of a complete rebuild of the 1987 Honda 250 ATV engine. The overall cost for this sponsorship is approximately $4,000.

Following this, the engine components such as crankshaft, head, engine block… are sent to their respective departments.

Each step is presented one after the other, below, with explanations and before/after pictures:

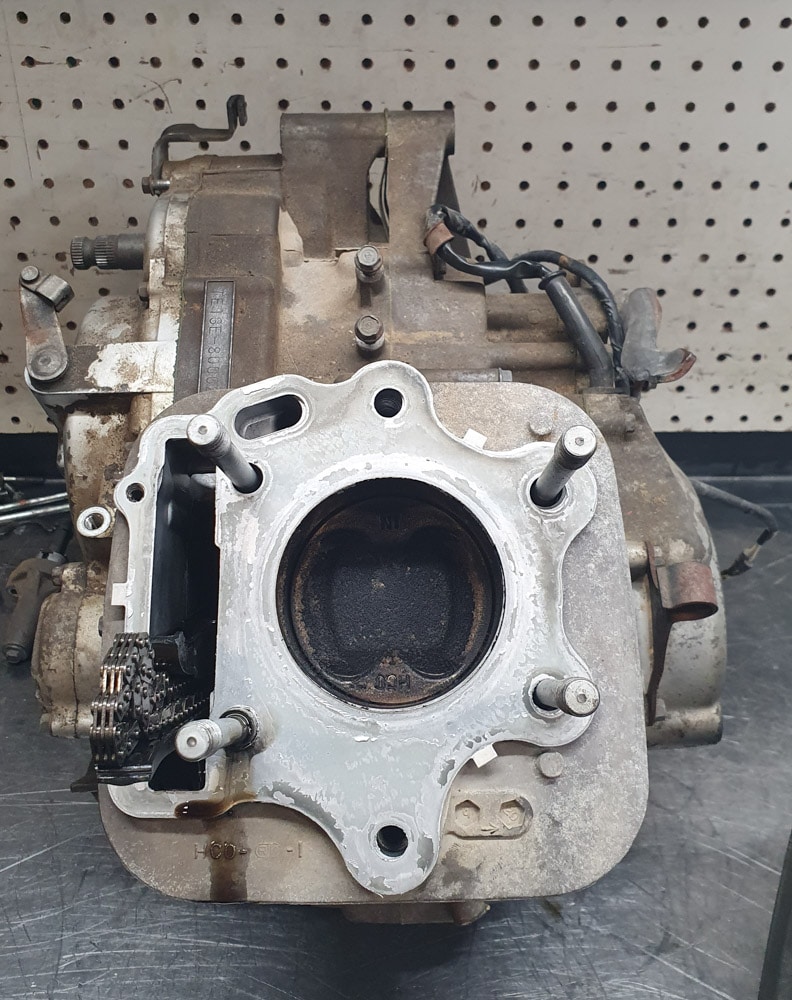

Cylinders :

Ultrasonic washing, inspection and various measurements to determine precisely what repairs need to be made.

Assignment of the serial number and production start.

The cylinder will go through ten or so steps to be replated by Nika-Tech and then finished to our strict standards.

Cleaning of the cylinder and evaluation to determine the state of wear of the part

Choose a refurbishment strategy: either change the cylinder sleeve or re-pierce it.

In this case, the cylinder was drilled to the correct size to fit the new piston.

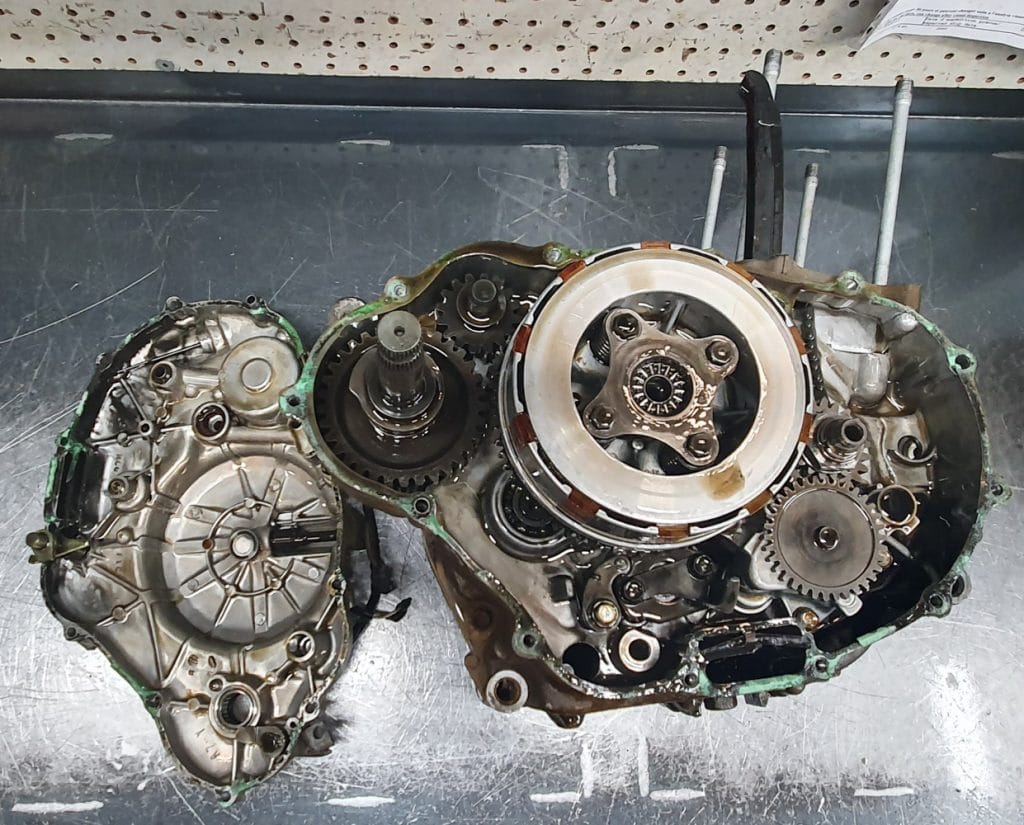

Crankshaft, head and engine block :

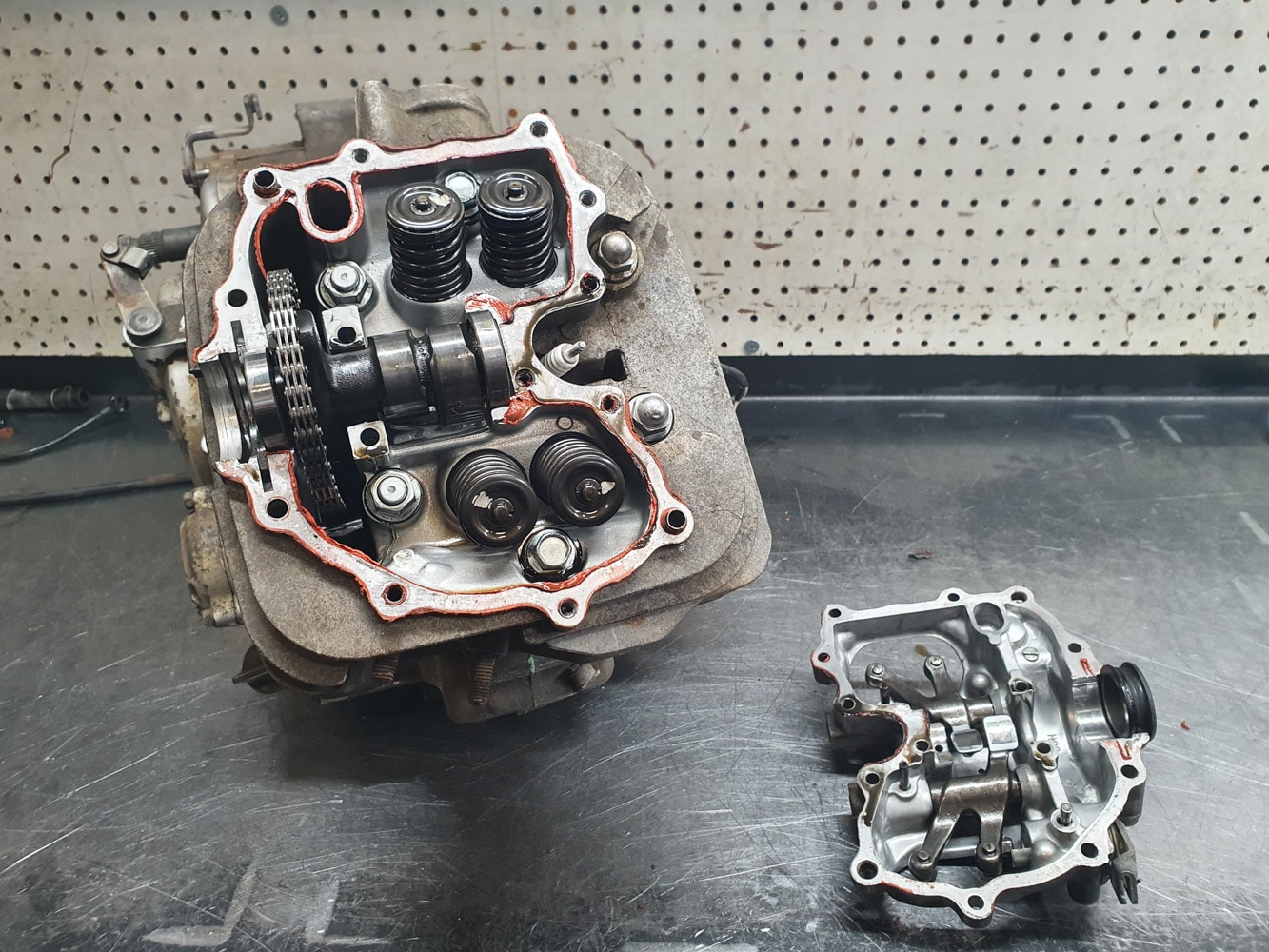

Disassembly of the different engine components allowing :

– A rigorous inspection and verification of the factory/series dimensions are respected;

– Identification of defective parts;

– Ordering of components to be replaced.

Washing/cleaning of parts

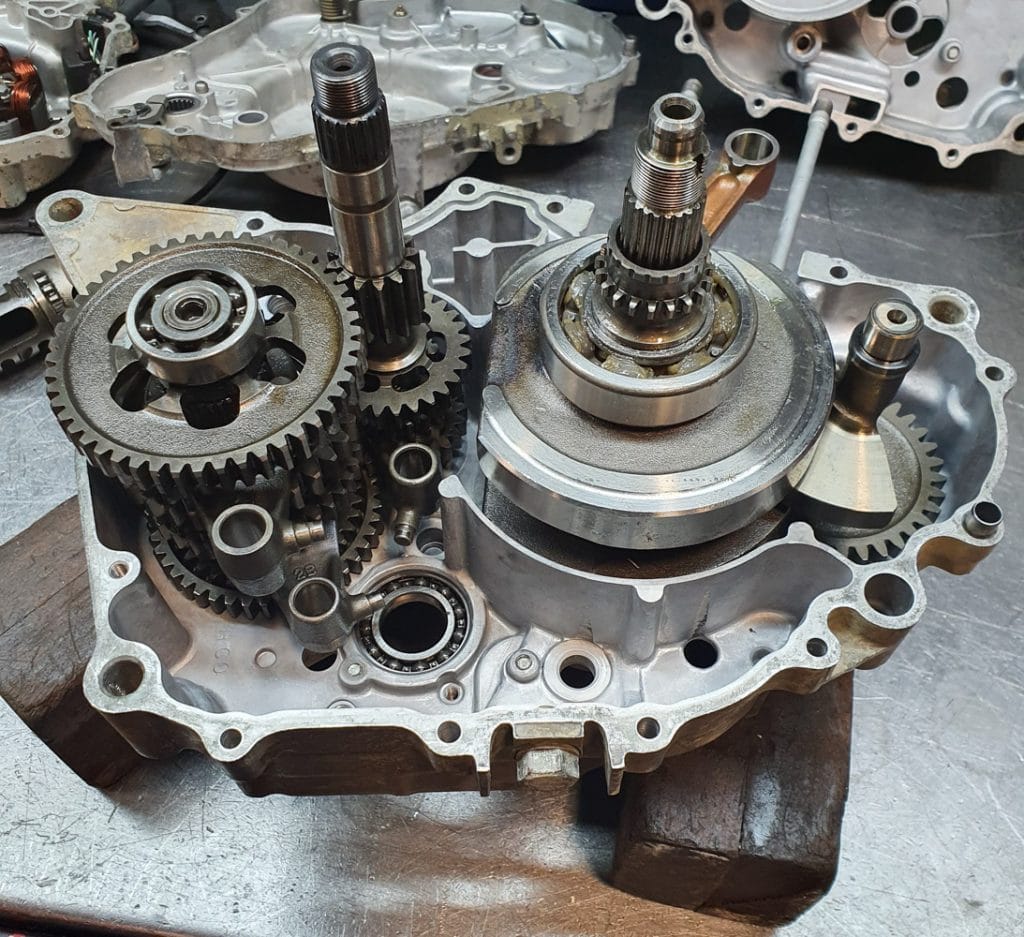

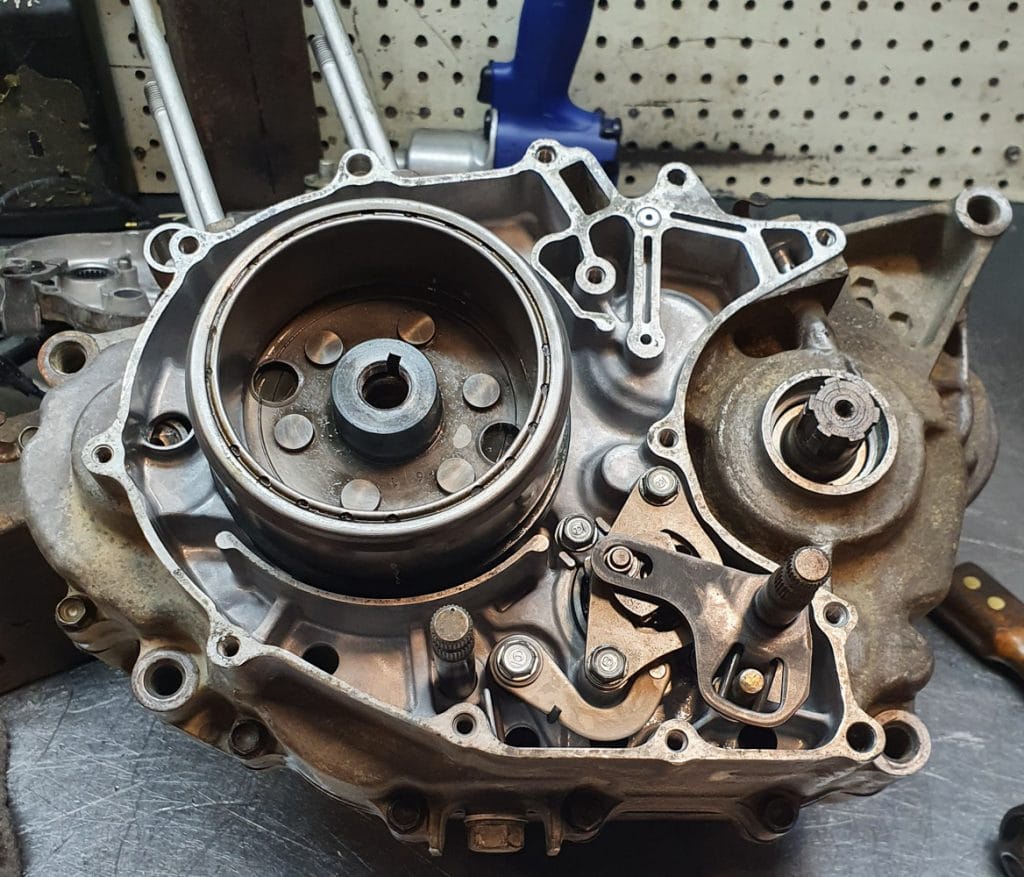

Reconditioning of parts of the 1987 Honda 250 ATV :

– Crankshaft: systematic replacement of bearings, verification of assembly clearances, reassembly to factory dimensions with a new connecting rod. The alignment of the crankshaft was checked.

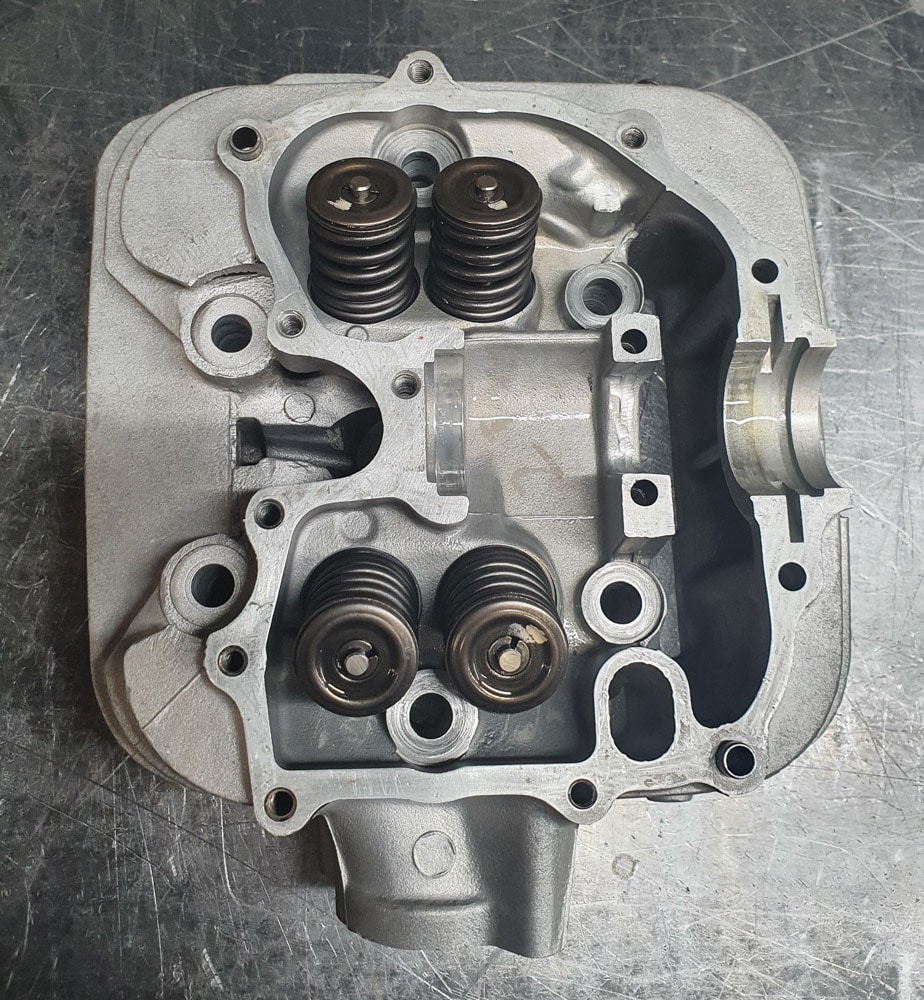

– Head: check of the valve guides, reworking and adjustment of the valve seats, rectification of the underside of the head. After reassembly, the head was subjected to a quality control including a leak test of the valves.

Throughout the assembly, the components are checked according to the technical manual.

Once the 1987 Honda 250 ATV engine is reassembled, there are several steps to check:

- Timing adjustments;

- Valve adjustments.

In this project, the engine was painted in ultra-coating and shock-resistant black (requiring 168 hours of drying time for a total cure) to match the needs of the sponsorship.

Since its creation in 1966, and thanks to its ability to adapt to changes (physical, human, financial, management, markets…), CVTech AAB has become the leader in the remanufacturing of engines and in the design and distribution of related parts for all types of motorsports vehicles.

Over the years, its expertise has enabled it to establish its reputation in Canada, the United States, Finland and many other countries around the world. The development and acquisition of new foreign markets are important axes for the company.

To date, close to 100 enthusiasts remanufacture engines, replace cylinders with Nikasil (the first Canadian company to introduce it), repair crankshafts and heads for ATVs, motocross, snowmobiles, personal watercraft, boats, etc.

Very soon, CVTech AAB will change its name. This is an opportunity for the company to consolidate its know-how, its added values, but also its customer experience (support and advice) that it wishes to bring to its customers to best meet their needs throughout the world.