In a previous article, we looked at the components of a cooling system and their roles. We also discussed the types of coolant that can be used in the system. In this issue, we’ll take a look at how to properly maintain a cooling system.

Consequences of not replacing the coolant it as recommended

Every manufacturer specifies the coolant replacement interval in the maintenance schedule in the owner’s manual. This interval is usually between two and five years.

Over time, coolant accumulates impurities and oxidation particles. In addition, the pH can change and its concentration increase. Crystallization may also occur within the cooling circuit.

Coolant pH

When the pH falls below 7, the acidity of the liquid increases, promoting corrosion inside the circuit. Aging coolant will actually have a higher acidity level, leading to corrosion of cylinder liners, cylinder block, cylinder head and other system components. Conversely, a higher than specified pH is also detrimental to the cooling system, as it can damage seals and softer metal components.

Mixing different coolants

For example, mixing a mineral-origin liquid with an organic-origin liquid could create sludge plugs in the cooling circuit. It is very difficult to remove this sludge completely.

Some mixtures can also produce very fine particles that act like sandpaper in the water pump.

So, a word of advice: don’t mix coolants with different characteristics!

Example of crystallization

A little anecdote:

The following example concerns a 2018 vehicle. The problem was detected in 2024, when the vehicle had less than 1,000 km. The manufacturer recommends fluid replacement every two years, which had been neglected.

Symptom:

After about 30 minutes of use, the overheating warning light came on. Fortunately, the user stopped the engine immediately, which prevented the worst from happening.

After inspection, it was found that the radiator was blocked by crystals.

Consequences:

The crystals formed deposits in the hoses, causing slight leaks as well as tearing the thermostat gasket.

Liquid lines and air vents were clogged.

The radiator was blocked.

The repair required almost complete dismantling of the engine to remove the crystals with a steel brush. In addition, several seals and the radiator were replaced, followed by a thorough flushing with water.

Checking your coolant

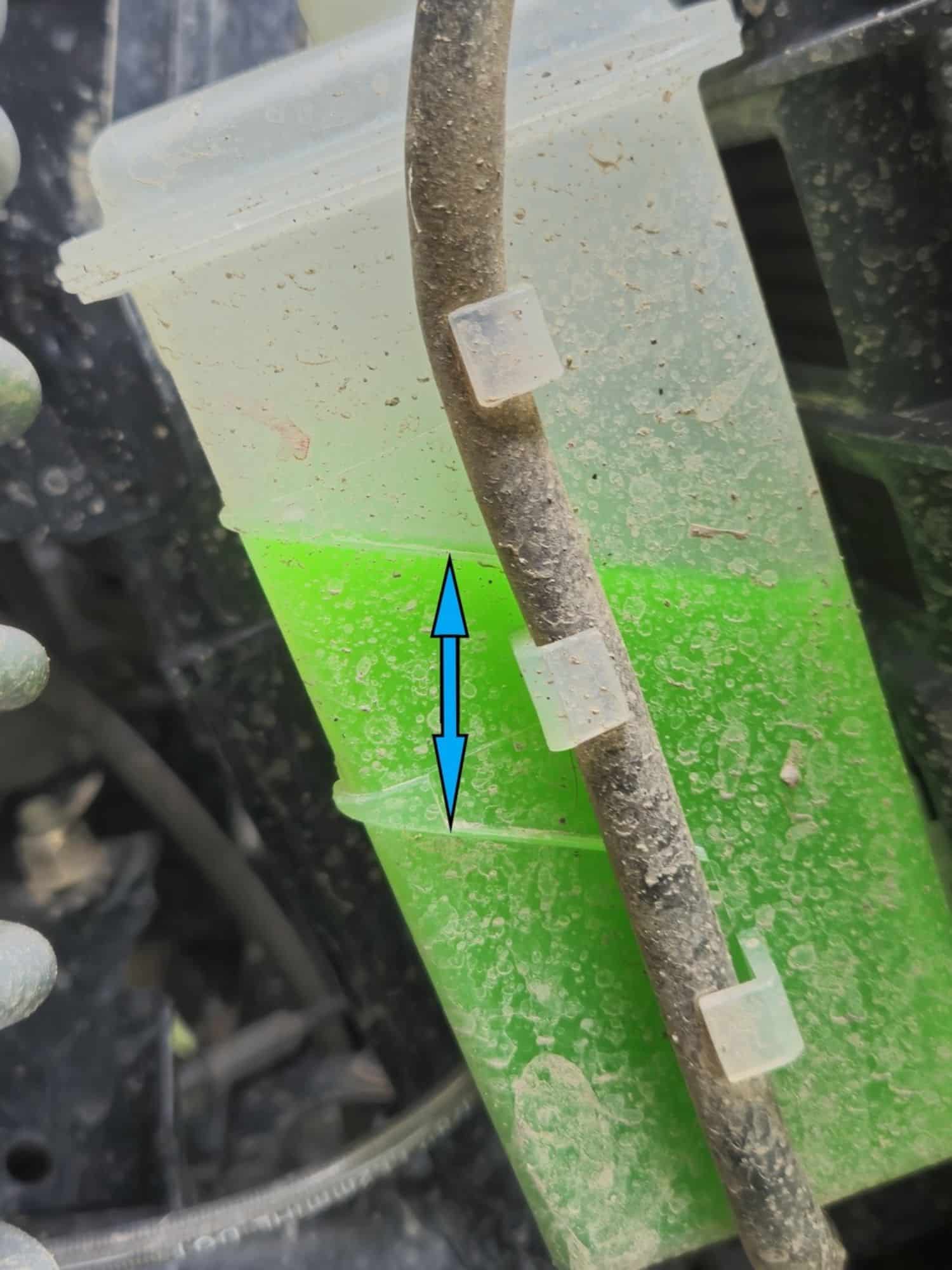

The level

Locate the expansion tank and check that the coolant level is between the “min” and “max” marks.

PH

The pH of the coolant can be measured using test strips. It’s important to know the pH of the coolant when it’s new, as it differs between short and long runs.

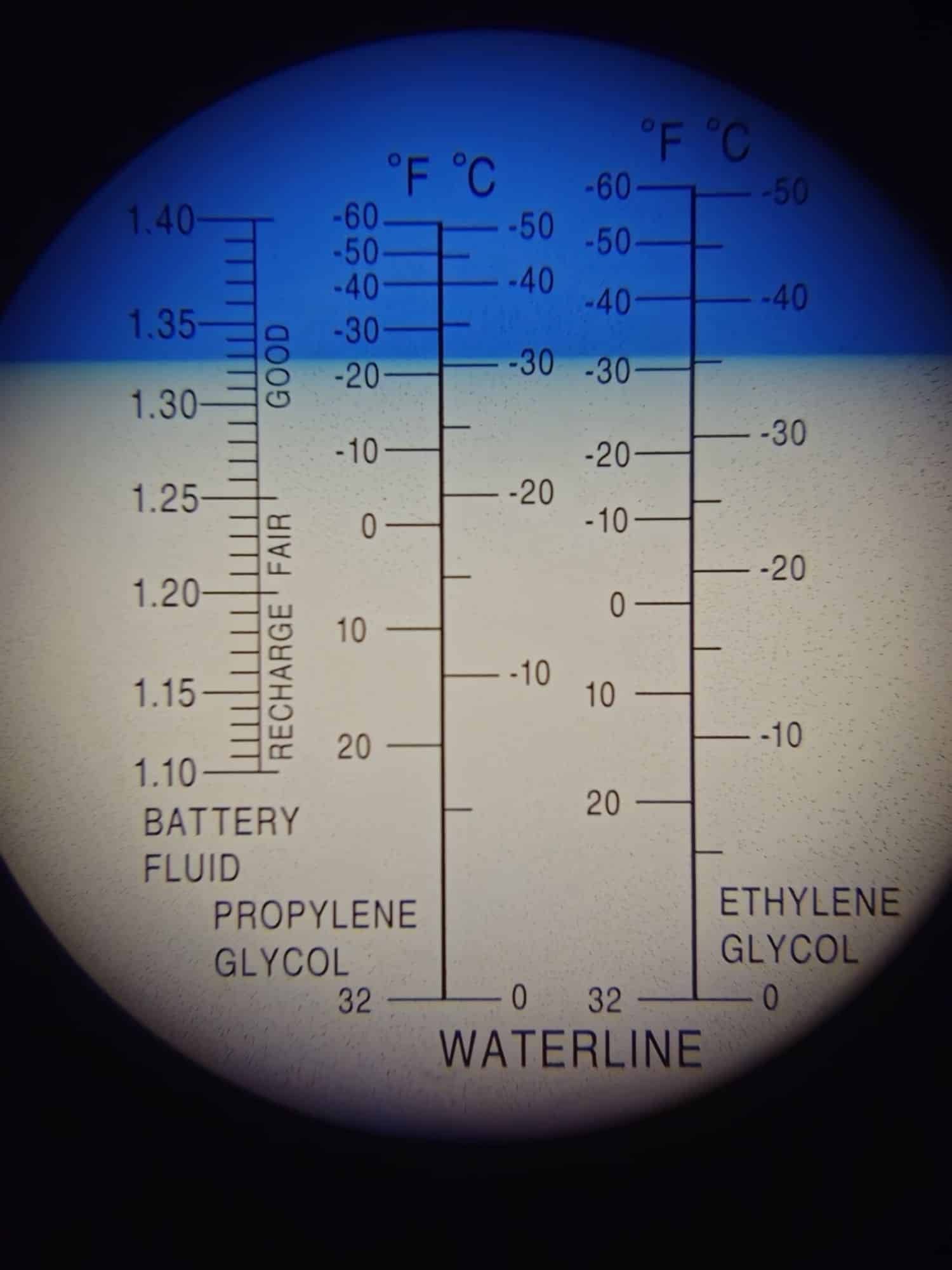

Concentration

Coolant concentration will increase with evaporation. Too high a concentration will result in reduced cooling system performance. Conversely, if the concentration is too low, there’s a risk of the engine bursting due to freezing.

A refractometer is the ideal tool for checking concentration. The level of concentration is proportional to the temperature at which the liquid will freeze, the norm being -37°C. If it is too concentrated, it must be diluted with distilled water. Unlike tap water, distilled water has a neutral pH and contains no minerals.

Coolant replacement

Draining

To replace the coolant, it is necessary to drain the radiator through its drain cock, or by removing the hose from the bottom of the radiator. Much of the coolant is also in the engine. Most engines have a drain screw, and you’ll probably need to consult the documentation to locate it. Once drained, replace the components.

Filling

Now it’s time to top up with new fluid. Make sure you use the fluid recommended by the manufacturer, preferably pre-mixed at -37°C.

There are two filling methods. There’s the vacuum method and the traditional method.

Traditional filling

From the radiator cap, add fluid to the correct level. If your engine is fitted with an air bleed screw, unscrew it until the liquid appears. Start the engine and refill the radiator. Repeat the operation until no more air escapes through the bleed screw. Then adjust the expansion tank level.

Vacuum filling

Vacuum filling has the advantage of preventing air pockets from becoming trapped in the cooling system. What’s more, filling is very quick. However, a tool and a source of compressed air are required. The principle is to create a vacuum in the cooling system and then draw new coolant into the engine. The level is then adjusted, the engine warmed up and the remaining air purged through the bleed screw.

In conclusion

Maintaining a ATV’s cooling system is crucial to keeping the engine running smoothly and preventing serious damage. Vehicle owners must pay close attention to the quality and type of coolant used, as well as its level and pH. Ignoring these aspects can lead to problems such as corrosion, deposit formation and even engine failure. Regular maintenance and adherence to the manufacturer’s recommendations will ensure the longevity and efficiency of the cooling system.