The vast majority of today’s vehicles have liquid cooling systems. However, their maintenance is often neglected, and sometimes even intentionally ignored. The consequences of neglecting your quad’s cooling system can range from negligible to complete engine destruction.

Why should this be? That’s what we’re going to look at with the different coolants, the consequences of a deteriorated coolant and the importance of proper cooling system maintenance.

Where does engine heat come from?

First of all, when a gasoline engine is running, it burns gasoline to transform its energy into mechanical energy. Combustion of the air-gasoline mixture reaches 1,500°C, and the engine cylinder wall reaches a temperature of around 200°C. What’s more, anti-pollution standards are forcing automakers to lean out the stoichiometric air-fuel mixture, thereby raising combustion temperatures.

Of the energy released by gasoline, only 25% to 41% is used to power your vehicle. At 41%, these are engines that operate on an “Atkinson” combustion cycle, which is only efficient in very specific circumstances. In motorsports, engines run on an “Otto” cycle. Older, less advanced carburettor engines had a fuel efficiency of 25% or less. The latest engines are around 30% and even 35% efficient. That said, all the rest of the energy contained in gasoline is mainly converted into heat, through both combustion and friction. This explains the extreme heat generated by mechanical systems. As a result, for every $10 of gasoline, only $3 actually moves the vehicle forward, the rest being lost in friction and heat.

This heat must be controlled, otherwise the oil will carbonize, the engine’s internal components will deform and expand, causing parts to tighten together, leading to engine destruction. Let’s take a look at how this heat is managed.

Firstly, around 30% of this heat is released through the exhaust, representing a net loss of energy. Next, some of the heat is dissipated by radiation, convection through the surrounding air, and the circulation of engine oil. Finally, the liquid cooling system dissipates around 30 to 40% of the engine’s heat.

In an automobile, the cabin heater recycles this heat, providing excellent energy recovery.

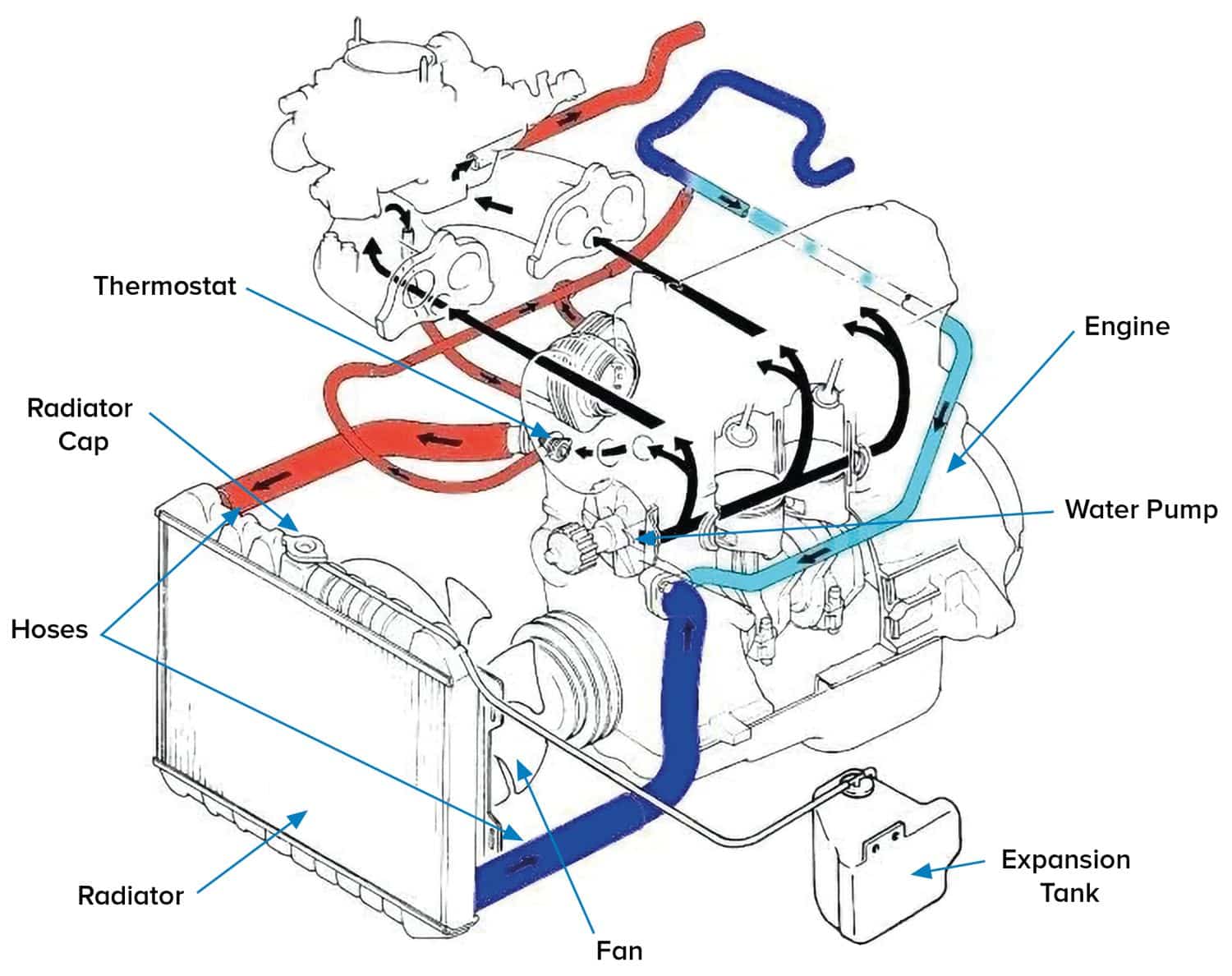

How a quad’s cooling system works

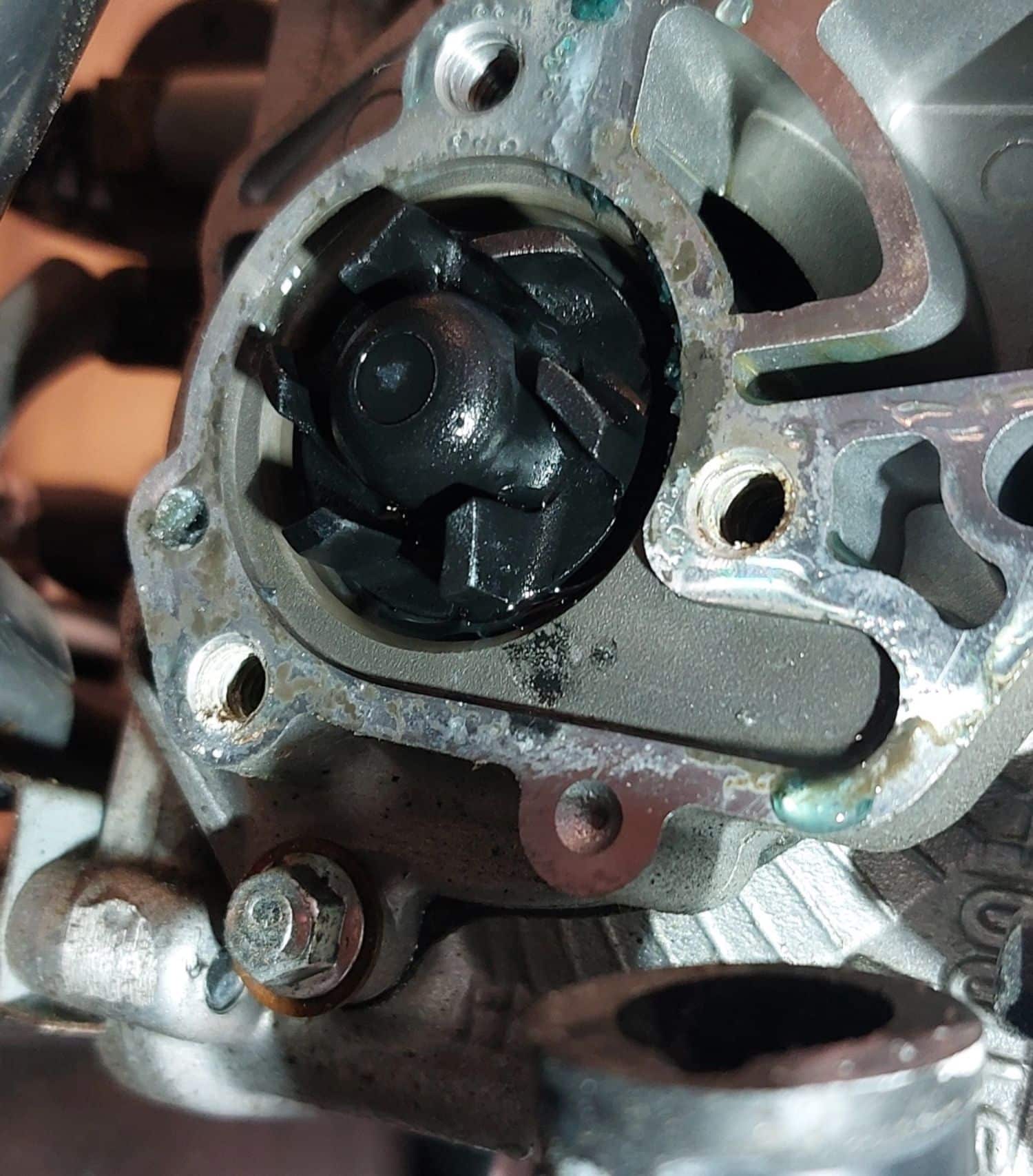

The water pump

Coolant is pumped into the cylinder head and around the cylinder liner to capture heat. A centrifugal water pump turns to circulate coolant through the engine and to the radiator.

Thermostat

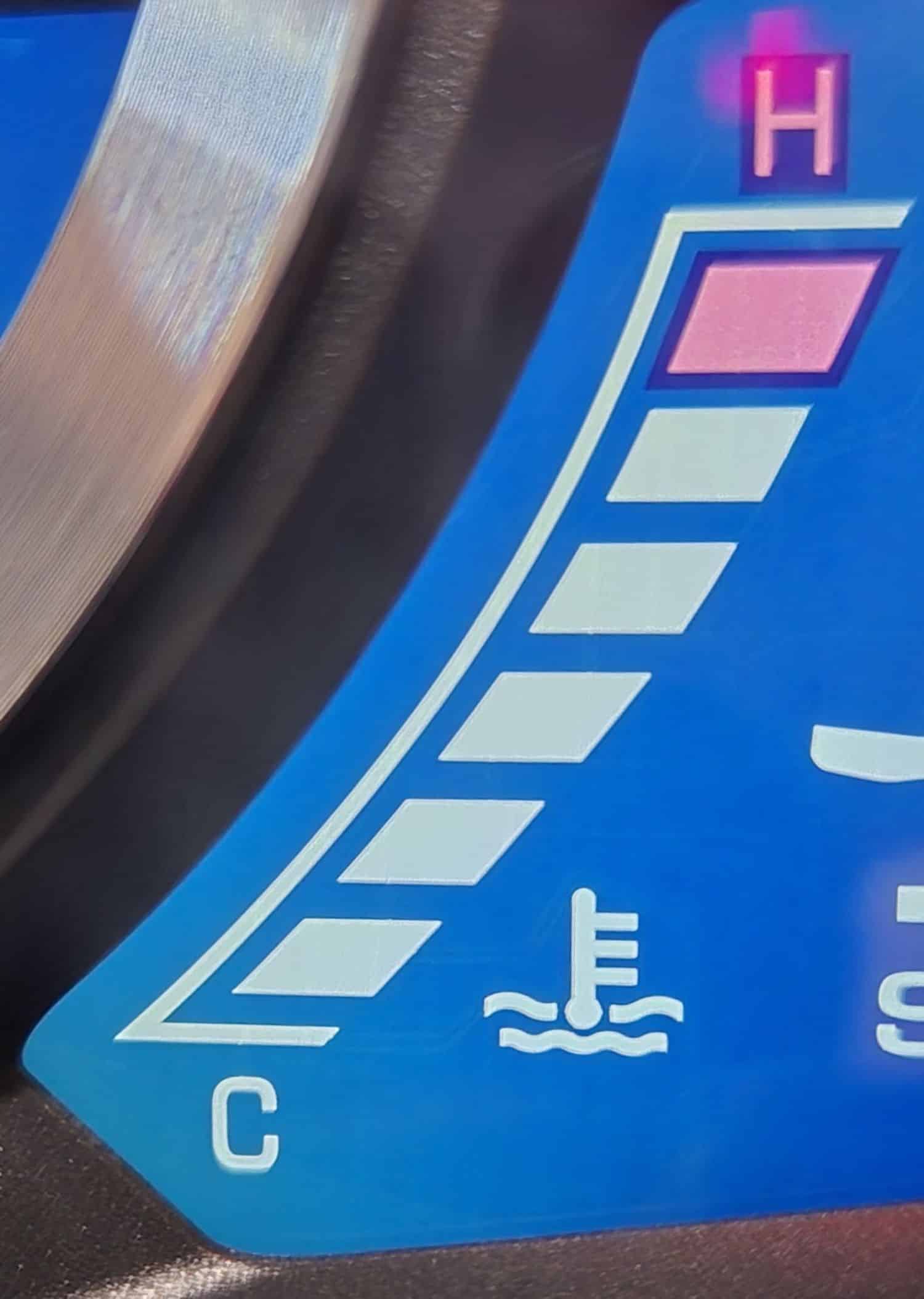

A thermostat regulates engine temperature. It blocks the flow of coolant to the radiator. The coolant then circulates in a loop through the engine to reach its normal operating temperature of between 85 and 95°C. If the engine runs continuously below this normal temperature, it will wear out prematurely. When the engine reaches 88-95°C, the thermostat gradually opens, allowing hot engine fluid to flow to the radiator through the top hose. At the same time, the amount of fluid leaving the engine is replaced by cooler fluid from the lower radiator hose. When the engine has cooled down sufficiently, the thermostat closes the passage to the radiator.

The radiator

The radiator, usually located at the front of the vehicle, is a heat exchanger. If the coolant inside the radiator becomes too hot, an electric fan is activated to draw air through the radiator and remove the heat accumulated in the coolant.

Cooling System

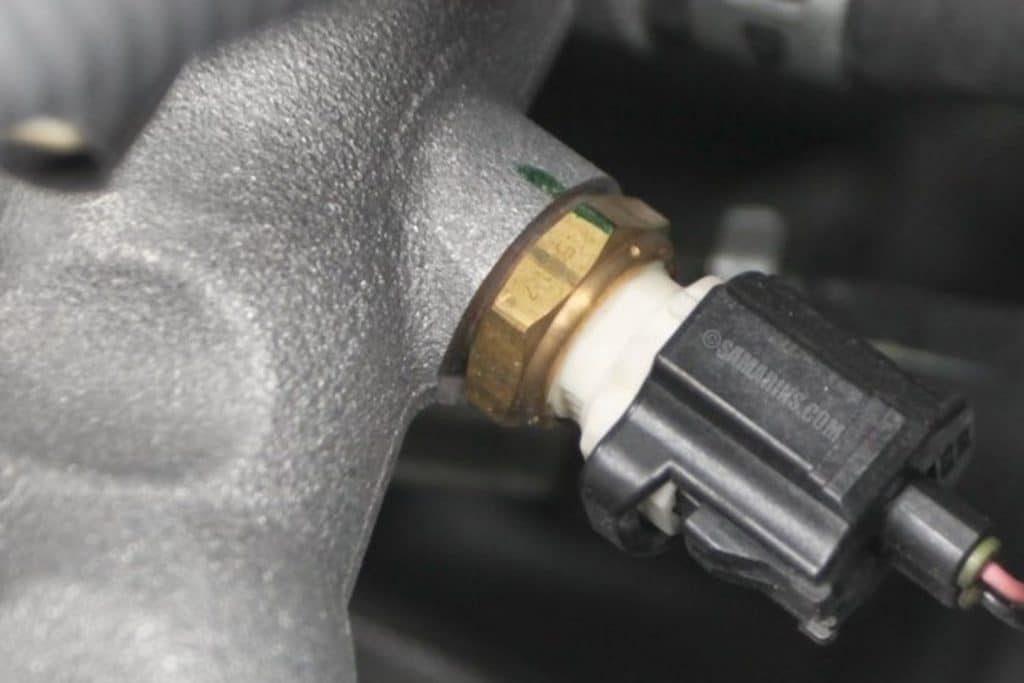

Temperature sensor

The motor is fitted with one or two temperature sensors. Their main function is to trigger the radiator fan. In addition, these sensors inform the engine computer of the temperature, in order to properly adjust fuel injection and ignition timing.

The radiator cap

The radiator cap is more than just a cap. In hot weather, system temperatures can reach over 105°C. How can this happen without the liquid boiling? The radiator cap maintains a pressure of around 15 psi in the cooling system, raising the boiling temperature to around 127°C at this pressure.

The expansion tank

When system pressure exceeds the calibrated pressure of the radiator cap relief valve, coolant drains into the expansion tank. As the engine cools, a second valve on the radiator cap allows coolant to flow back into the engine.

Bleed screw

Many cooling systems are equipped with an air bleed screw. This screw is strategically positioned to extract air trapped in high areas of the cooling system during refilling.

Different coolants

Now that the configuration of an engine cooling system is well known, let’s move on to the coolant itself. The first thing to remember is that not all coolants are created equal. Even those of the same color have different chemical compositions. What’s more, the pH varies from one type to another, and the base composition may be ethylene or propylene, which also affects the life of the liquid, which is specific to each formulation.

Green coolant

Its basic composition may be ethylene glycol or propylene glycol. It is silicate-free, but contains organic acids. Its pH is generally between 10 and 11, and its service life is usually around two years. Blue coolant is very similar, but not compatible.

Pink coolant

Pink coolants are usually based on ethylene glycol, although propylene can also be used. They use a long-lasting organic acid technology known as “HOAT”. Their pH is between 7.5 and 8.6. Other pink coolants may contain long-lasting octoic acid (“OAT”) instead of organic acids. These two types of coolant are not compatible.

In all cases, coolants contain corrosion inhibitors to prevent engine components from oxidizing.

There are many different types and colors of coolant. These examples represent only the most commonly used in motorsports. Despite similar colors, the chemical composition differs considerably. If you’re shopping in the automotive department, the choice becomes even more complex.

In another article, we’ll take a look at how to properly maintain your cooling system.